The pizza industry has witnessed exponential growth over the past few decades, evolving from a traditional Italian dish into a global phenomenon. From artisanal wood-fired pizzas to frozen supermarket varieties, consumer expectations have become increasingly diverse. Meeting this demand at scale while maintaining the quality and authenticity of the product requires cutting-edge technology and carefully designed production lines.

Pizza production lines have come a long way, incorporating advanced automation, robotics, and sustainability practices to optimise every stage of the process. In this article, we delve into the latest advancements in pizza production technology, focusing on critical areas such as dough handling, topping application, baking, and sustainability. We also highlight leading equipment manufacturers such as AMF Bakery Systems, Rademaker, Grote Company, Quantum Technical Services, and Naegele Inc., whose innovations are driving the industry forward.

Advancements in Dough Handling

Dough handling is the cornerstone of any pizza production line. Whether a pizza features a thin, crispy crust or a thick, chewy base, the dough’s quality significantly influences the final product. To achieve consistent results, modern production lines have embraced automation that ensures uniformity while reducing manual labour.

AMF Bakery Systems has emerged as a leader in this space, offering modular systems that can produce a wide variety of crust types. Their solutions not only streamline dough mixing and sheeting but also incorporate precision rollers and cutting tools to maintain the integrity of the dough’s gluten structure. This modularity allows manufacturers to switch between different pizza styles seamlessly, catering to varying consumer demands.

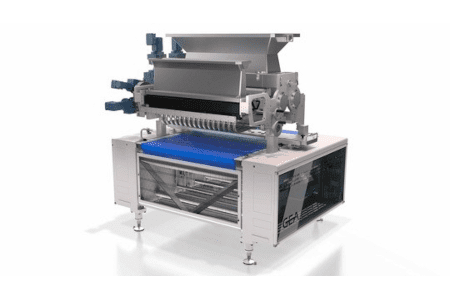

Similarly, Rademaker specialises in flexible dough sheeting and laminating systems that ensure consistent thickness and texture. These systems are designed to handle both high-hydration doughs for Neapolitan pizzas and dense doughs for thick crusts. Their precision sheeting technology guarantees that each crust meets exact specifications, minimising waste and maximising yield.

Yet, automation in dough handling goes beyond efficiency. It also addresses challenges unique to mass production, such as hydration and elasticity. Dough that is overworked during production can lose its desirable texture. To combat this, manufacturers are developing innovative vacuum-based systems that gently process dough without compromising its quality.

AM Manufacturing offers additional solutions, such as the Tor-O 2000, which automates critical steps like dividing, rounding, proofing, and pressing. These features are particularly valuable for manufacturers producing large quantities of pizza crusts while maintaining artisanal characteristics.

Topping and Customisation Innovations

Topping application is one of the most complex stages of pizza production, requiring a combination of precision, speed, and flexibility. From classic margherita pizzas to loaded supreme varieties, consumer preferences demand highly accurate and even topping distribution.

Grote Company has developed a range of applicators specifically designed for pizza production. Their systems ensure precise placement of sauces, cheeses, and other toppings, minimising waste and improving product consistency. Grote’s equipment can handle high-speed production lines, making it an ideal choice for large-scale manufacturers.

For smaller or artisanal producers, Quantum Technical Services offers innovative topping dispensers that allow for quick adjustments and customisation. These systems are particularly suited to operations where multiple pizza recipes are produced on the same line. Their equipment is also easy to clean and maintain, reducing downtime between product runs and improving overall efficiency.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Bakery

X: @int_bakery

YouTube: @Bakery-TV

Media contact

Joseph Clarke

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com