Efficiency is a primary concern for industrial bakeries, where production lines must operate seamlessly to meet consumer demand. Conveyor systems are essential in reducing manual handling, minimising downtime, and optimising throughput. The design of conveyor belts directly impacts speed, energy consumption, and overall productivity, making innovation in this area a key focus for manufacturers.

Modern bakery conveyors are engineered to provide gentle product handling, reducing breakage and ensuring uniformity in baked goods. Companies such as AMF Bakery Systems and Dorner Conveyors offer solutions designed to maintain product integrity while maximising throughput. Their advanced belt materials and configurations help prevent damage to delicate items like pastries, cookies, and cakes during transportation.

The integration of automation and smart technologies has further transformed conveyor efficiency. Ashworth Bros., Inc., a specialist in conveyor belting solutions, provides hybrid belts that combine metal and plastic elements to enhance tracking and durability while improving performance in automated settings. Intralox, another leading provider, offers activated roller belt (ARB) technology, which allows precise sorting and merging of baked goods without manual intervention. These innovations help bakeries maintain steady production flow while reducing labour-intensive processes.

Another significant factor in conveyor efficiency is energy consumption and sustainability. Habasit and Forbo Movement Systems manufacture lightweight, low-friction conveyor belts that reduce energy usage while maintaining high performance. Energy-efficient motors and variable-speed drive systems, provided by companies like SEW-Eurodrive, allow bakeries to adjust conveyor speeds based on production needs, reducing waste and lowering operational costs.

Challenges in maintaining efficiency include equipment wear and tear, misalignment, and inefficient facility layouts. Predictive maintenance solutions, powered by IoT-enabled sensors, are increasingly used to detect early signs of failure and schedule repairs before breakdowns occur. Companies such as Flexco and Rexnord develop real-time monitoring systems that track belt performance and detect anomalies, helping bakeries avoid costly downtime.

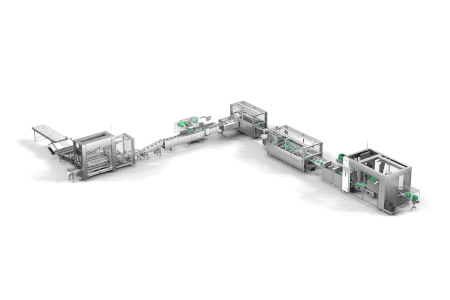

To further enhance efficiency, many manufacturers opt for modular conveyor designs that enable quick reconfiguration based on production changes. SpanTech and Modu System specialise in modular conveyor solutions that provide flexibility for bakeries needing to adapt to seasonal demand fluctuations or new product lines.

By leveraging these advancements in belt and conveyor technology, industrial bakeries can significantly improve efficiency, ensuring higher productivity, reduced operational costs, and a more consistent final product.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

LinkedIn: International Bakery

X: @int_bakery

YouTube: @Bakery-TV

Media contact

Joseph Clarke

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com