Daxner will be presenting its solutions for the food, animal feed and chemical industries at Powtech, which is being held parallel with FACHPACK this year, from 27 to 29 September in Nuremberg

“After two years without Powtech, we now have the opportunity to welcome new and familiar faces at our booth again,” said Christian Daxner, CEO and Owner of Daxner GmbH. “In addition to our three product highlights at the booth, our visitors can gain realistic insights into real plants by means of VR glasses.”

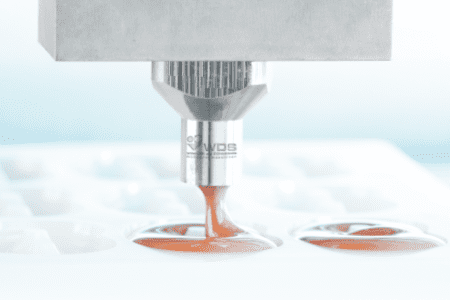

For the first time, Daxner will be showing its control screening machine VIB & PRESS in a new design. The machine is used for the intake and control screening of powdered products, particularly products that tend to clump. Using the VIB & PRESS two processes are carried out simultaneously: the vibrating screen performs the screening action, the products are pressed through the flat screen using variable speed.

The company will also be showing its dosing and screening machine DM30 Easy Clean which combines a dosing and screening unit, to save space and reduce costs. The metering and screening unit can be easily pulled out for inspection, making inspection of the interior and product chamber possible. If the screen basket needs to be changed this can be done quickly and conveniently.

The container discharge system Daxer Container System (DCS) is used for safe and gentle discharge of bulk materials with poor flow characteristics. The DCS is in a compact design, offering flexibility, hygiene and freedom from contamination for the operator. At Powtech, the company will show a container with a complete discharge station including an automatic flap opener. A major advantage of this system is that the container can be positioned in hard-to-reach places.

“At our booth, our visitors can use VR glasses to gain real insights into real complete systems,” explained Mr Daxner. During the virtual tour, the systems of different industries can be virtually walked through and new perspectives can be opened up. “This technology is perfect for giving our customers an impression of how the overall plant will be designed in the end.”

Read more latest industry news and developments in our free to download magazine.

Media contact

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com