A seasoned team of experts at TNA solutions’ manufacturing facility in the UK invited International Bakery to have a look at the solutions they create for the snacking market

The International Bakery Team had the utmost pleasure of being invited to TNA’s Open House event on 16 August 2023, based at the company’s manufacturing facility in Birmingham, UK.

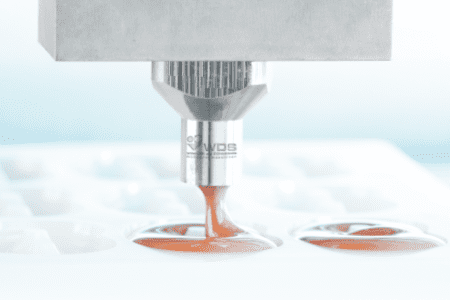

The company showcased its comprehensive line of solutions spanning packaging, seasoning, feeding and distributing, demonstrating an embrace of digital technologies with a whole host of benefits, including making the lives of the operators easier and satisfying consumers.

Sustainable savings

Several of TNA’s solutions were first showcased at interpack, as the first edition in six years provided the opportunity to highlight progress made in the last six years which, for TNA, includes increasing machine modularity, flexibility with seasoning but also, notably, sustainable production.

TNA’s approach to sustainability can be summarised by three pillars; people, planet and prosperity, acknowledging that in order to achieve greater sustainability in the industry, these three areas must be taken into account.

In the context of production, TNA has introduced a sustainability packaging calculator for producers to utilise, to calculate exactly how much they could save – both costs and CO2 – in production by reducing the amount of plastic used per bag.

“We’re changing from what is typically a 12 millimetre or nine millimetre seal down to seven or five millimetres,” explained Simon Hill, Group Solutions Specialist – Packaging. “We started this at interpack and we’re showing this solution off to a lot of our customers.

“This is a good way of showing customers proven benefits of reducing a smaller end seal on each bag and reducing the footprint.”

Producers can input into the sustainability packaging calculator their roll length and end seal length and what it’s being reduced to. By doing so, the calculator churns out the total cost of money saved per month, alongside how much CO2 is reduced.

“A lot of our customers have CO2 reduction targets to meet,” said Simon Hill. “This is on our website and will be at every exhibition now over the next few years,” he added, as part of an “awareness piece”. “Lots of our customers have no clue about sustainability savings.”

As part of a wider push for greater sustainability, TNA are also introducing recyclable films. This includes, “Biodegradable films, mono polypropylene and paper laminates – although our major client base is snack goods and confectionery, where paper isn’t the best in terms of shelf life.”

Small steps such as adding white etching to the inside of the bags have helped to increase the number of snack bags that are recycled, as a common issue for the industry is that in recycling streams cameras fail to detect the bags as plastic and they are not sent to be sorted off in a plastic recycling stream.

Packaging and distributions

Also showcased at interpack was TNA’s ropac® 5, a case-packing system designed for flexible bags and capable of handling up to 220 bags per minute. The system caters to the packaging needs of small-to-medium companies…

Read the full feature in our free to download magazine.

Never miss a story… Follow us on:

![]() International Bakery

International Bakery

![]() @int_bakery

@int_bakery

![]() @Bakeryint

@Bakeryint

Media contact

Caitlin Gittins

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com