Rodrigo Castaneda, VP/GM of North America at TIPA, discusses the shift towards compostable packaging, highlighting the industry’s path to a sustainable future

What are the primary challenges in developing compostable packaging solutions to maintain the same level of functionality and durability as traditional plastics?

One of the biggest challenges is developing compostable packaging that matches the functionality, durability, and protective qualities of traditional plastics. These include achieving high barrier properties to protect contents from moisture and oxygen, ensuring sealing strength, and maintaining flexibility and transparency. To meet these needs, formulations of compostable polymers are key. This technology ensures that compostable packaging performs just as well as conventional plastics in various applications, including the packaging of food and various other consumer goods.

How do you envision the adoption of compostable food packaging impacting consumer behaviour and waste management practices?

The adoption of compostable food packaging has the potential to shift consumers towards more sustainable habits to reduce plastic waste. As consumers become more aware of the impact of plastic waste, they are more likely to prefer products with eco-friendly packaging. This shift can lead to increased pressures on retailers and, in turn, manufacturers to make compostable packaging options more prevalent. These practices can catalyse better overall waste management practices as compostable packaging can be disposed of in-home composting systems, reducing the amount of waste that is not or cannot be treated by traditional recycling infrastructure.

How can we educate the industry in the transition from traditional plastics to compostable packaging?

Educating the industry involves a multi-faceted approach. It includes raising awareness about the environmental benefits of compostable packaging, providing information on the performance and capabilities of these materials, and offering guidance on integrating compostable solutions into existing manufacturing processes. Collaboration with industry leaders, policymakers, and waste management entities through advocacy and training measures is vital for ensuring a more widespread transition to compostable packaging. Ultimately, this will benefit the planet and help consumers, companies, and localities navigate quickly changing policies on packaging and plastics.

How do new compostable closures address the limitations of current recycling and composting infrastructure?

Traditionally, closures on plastic packages are formulated using different plastic polymers that are hard to recycle and impossible to compost. This combination of different types of plastic in a single package makes handling, sorting, and recycling much more complicated, and many sorting facilities do not have the technology or time to deal with such plastics. Thus, many multi-material plastic packages end up being incinerated or landfilled, significantly contributing to planet-warming greenhouse gases.

New compostable plastic closures address this issue by providing an ‘all-in-one’ solution that can be fully disposed of in an at-home compost bin or at an industrial composting facility. These advancements in engineering bring more compostable packaging to the market and allow for composting at home. It also reduces the need for industrial composting facilities and mitigates the issues associated with plastic film recycling, such as contamination and complex sorting processes. These closures offer an easy and effective way for consumers to dispose of packaging, promoting a more circular approach to waste management.

What key technological advancements have enabled this kind of innovation, and what potential do they hold for future innovations?

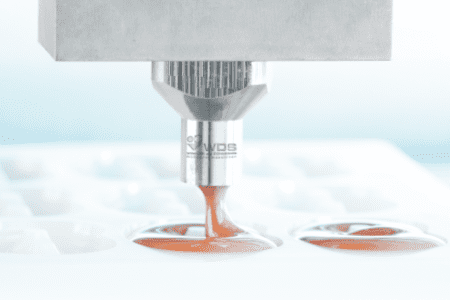

The research and development of compostable plastic polymers in recent years has allowed the plastics industry to develop polymers that fully break down under composting conditions. These high-performance properties such as durability, flexibility, and transparency mimic those of conventional plastics. Advancements in technology, and chemical and material engineering have been key. Advances in laboratory settings with advanced machinery, like on-site compounders, combined with the computational capabilities of machine learning and big data have come a long way. Today there are increased capabilities to parse large databases of compostable polymers to come up with new formulations at reduced R&D timelines.

In what ways can bakery and other food businesses integrate compostable packaging into their supply chains without compromising efficiency or increasing costs?

Food businesses and bakeries can integrate compostable packaging by choosing solutions that are compatible with their existing products and equipment, therefore avoiding extra costs for specialised machinery or design. Additionally, businesses can leverage partnerships with an increasing number of local packaging manufacturers and suppliers to access cost-effective compostable materials and scale purchasing to reduce costs. Education on the long-term environmental and brand benefits of sustainable packaging can also help justify initial expenses.

What will it take to support and promote the widespread adoption of compostable packaging solutions?

Supporting the widespread adoption of compostable packaging solutions requires a collaborative effort from various stakeholders. This includes continued innovation in compostable materials from suppliers, government incentives and regulations promoting sustainable packaging, broader waste management facilities for composting and accepted materials, and consumer education on the benefits of compostable options. Industry partnerships and investment in infrastructure for composting are also critical to enhancing this transition.

What challenges might arise when trying to increase the widespread adoption of compostable packaging?

Traditionally, the industry’s biggest challenges have been the higher cost of compostable materials compared to traditional plastics, the need for consumer education on proper disposal methods, and the limited availability of composting facilities in some regions. Overcoming these challenges involves addressing cost barriers through technological advancements and provisions like EPR, which include responsibility for mitigating the environmental impact of packaging. Additional steps to address these challenges include expanding composting infrastructure, and raising awareness about the environmental impact of compostable packaging.

Do you think that legislation or regulations can/will help the transition towards a more sustainable industry in the future?

Absolutely. Policy and regulations play a significant role in this transition. Policies that require the use of eco-friendly packaging provide incentives for sustainable practices and set standards for compostable materials that will drive adoption. Regulatory support is vital for top-down stimulation of investment in research and infrastructure.

We have seen encouraging trends in Europe, North America, and on a global level with policies that are likely to encourage increased awareness and adoption of sustainable and compostable packaging. Recent steps include the EU’s Packaging Waste Directive, which will have far-reaching effects on the way brands package their goods and the way consumers handle their packaging waste. In the US, lawmakers are increasingly introducing and advancing related legislation, including the federal Recycling and Composting Accessibility Act. International initiatives like the UN Environment Programme’s efforts to create a Global Plastics Treaty also underscore the growing prominence of policy conversations aimed at combating plastic waste and fostering eco-friendly innovation.

How do you see the industry landscape changing over the near future?

We’re likely to see a shift towards more sustainable practices with increased adoption of compostable packaging. Technological advances will continue to improve the performance and cost-effectiveness of these solutions. As consumers demand more eco-friendly products, businesses will increasingly prioritise sustainable packaging. The expansion of local production capabilities in the US will further promote sustainable supply chains by reducing transportation emissions and supporting local economies. Collaboration across the supply chain and supportive regulations will be crucial in accelerating this transition, reducing plastic waste, and moving towards a circular economy.

Any final thoughts you would like to add?

The transition to compostable packaging presents both challenges and opportunities for the industry. The development of compostable polymers that match the performance of traditional plastics is critical to ensuring the viability and effectiveness of eco-friendly packaging solutions. As consumers become more environmentally conscious, the demand for sustainable packaging options is likely to increase, driving further innovation and adoption. Education and collaboration among industry stakeholders, policymakers, and waste management entities are essential to facilitate this transition.

To support widespread adoption, it is imperative to continue investing in research and development to improve the performance and cost-effectiveness of compostable materials. Government incentives and regulations will play a crucial role in promoting sustainable practices and setting standards for compostable packaging. Expanding composting infrastructure and raising consumer awareness about proper disposal methods are also vital steps in this journey.

Ultimately, the transition to compostable packaging requires a collective effort from all stakeholders. With continued innovation, supportive regulations, and increased consumer awareness, the industry can move towards a more sustainable and environmentally friendly future. This shift will not only reduce plastic waste but also promote a circular economy, benefiting both society and the environment. The journey ahead is challenging, but the potential rewards for our planet and future generations make it a worthwhile endeavour.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

International Bakery

@int_bakery

@Bakeryint

Media contact

Joseph Clarke

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com