Alternative ingredients for vegan or gluten-free doughs as well as fruit doughs and pastry are challenging applications. Mixing technologies must be mindful, warns Editor Joseph Clarke

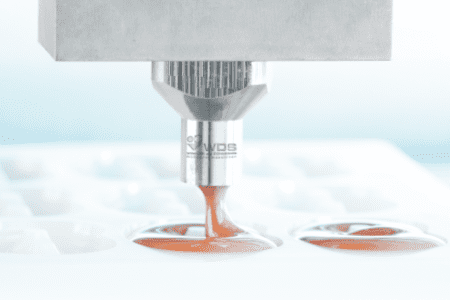

Mixing technologies have a greater challenge on their hands today as alternative ingredients are being added to the mix, meaning the rheology and characteristics of the dough and how they are mixed is impacted upon. Automated equipment to increase capacity, efficiency and alleviate pressures from manufacturers in addressing labour shortages continues to play a major part in the kind of equipment released to market. Developments in the design of mixing technologies such as temperature sensors, programmable controls and variable speed capabilities have assisted with ticking these boxes and more.

The consumer of today is discerning, selective with their spend and would still like to continue to indulge in bakery products, which have remained steadfast as an affordable indulgence against a backdrop of rising prices. Although traditional bakery products continue to have their place, some consumers are enticed by clean label baked goods formulated with natural ingredients, as well as alternatives for gluten-free or plant-based consumers and artisanal products for their connection with quality.

The growth in these markets has meant the ingredients and equipment that serve these products need to adjust accordingly. Plant-based products have brought plant-based milks, plant-based fats and egg replacers into the fray. Subsequently, mixing technologies need to take into account how these ingredients will react during processing, while ensuring proper emulsification, aeration and texture development. Artisanal products, meanwhile, have witnessed experimentation with heirloom grains, specialty flours and longer fermentation processes to develop distinctive flavours. Mixing equipment, for example, will need to accommodate for these longer fermentation times.

The result of this has been a wider variety of doughs to be processed, some of which are formulated with clean labels and natural ingredients – which typically stipulates the absence of additives, preservatives and artificial flavourings. The interest in high fibre content has been influential in how bakers have approached imbuing baked goods which has included formulating with whole grain flours such as barley, rye and spelt, using high-fibre additives and sweeteners, as well as added fibre-rich inclusions like seeds and nuts.

All of these trends set the backdrop for how machinery manufacturers have to come up with solutions that can handle alternative ingredients and processing, as they respond to their customers’ requirements who are looking to tap into these trends and growth opportunities. Some common themes have emerged from new mixing technologies such as the embrace of digitalisation and automation; refined monitoring and control systems; energy efficiency; hygiene prioritisation and customisation and adaptability.

Scaling up with automated equipment

The increase in automated bakery equipment, partially in response to skilled labour shortages, has manifested in a number of ways. Within mixing technologies, the possibilities for designing or redesigning equipment have seemingly appeared endless, as machinery manufacturers have strived to offer mixers that are more efficient, cost-effective and above all else, sensitive to their customers’ needs.

“Our guiding principle is that the recipe of the dough must not change when mixing, the equipment has to adapt to the recipe,” explained Werner Koetz, Master Baker at Koenig Maschinen. “Mixing times can vary, but the recipe of a product should never change as this is the unique characteristic of every baker.”

Koenig’s mixer program includes a spiral mixer, twin twist mixer and a bowl hoist for supplying the lines with mixed dough and ranges in dough capacities – from 125kg to 240kg.

“The interaction of tool speed, speed and direction of rotation of the mixing bowl can be precisely coordinated with all mixers and stored in the program in different languages,” said Werner. “Thus, the Koenig mixers can be used universally. A temperature sensor provides information about the temperature of the dough.”

For a lot of bakery businesses, there are lots of questions to be asked about how to modernise their operations and scale up appropriately to meet this continually growing demand for baked goods. Automated, industrial operation helps to eliminate common human error, increase efficiency and ensure consistency and repeatability.

Scaling manufacturing operations can be trickier than it seems, as it requires more than just increasing the size and scale of the operation, but it also needs to be able to manage elements such as the process itself and parameters related to the dough in real-time. Automating the mixing process represents one significant step towards scaling manufacturing and has to be done right.

Continuous mixing is well suited to industrial processing of a larger scale in particular, because of its ability to ensure consistency at the beginning of the process, consequently resulting in reduced product waste. In one example, Zeppelin Systems worked with Ditsch in implementing their continuous mixing system, the results of which were saving approximately 40% of the mixing and kneading time enabling faster dough development, all translating into increased production capacity.

One advantage of employing the continuous mixing system was the improvement in dough quality, by making it more uniform and easier to process, while another advantage was the enhanced process control as the system comes equipped with digital controls that enable for precise monitoring and adjustment of various parameters that are important to the mixing process – such as temperature levels and pressures. The dough temperature can be controlled by adjusting the temperature of the additional water and utilising the cooling jacket which is installed on the mixer.

Failing to properly mix dough can have a big impact for bakeries, namely resulting in product waste. Silverson, in working with a bakery making crumpets to optimise their process, acknowledged in a case study that the bakery’s quality control system rejected products that did not meet parameters in terms of diameter, shape, thickness and colour – in total, two tonnes of wasted crumpets per day and accounting for millions of dollars’ worth of rejected product a year.

In tackling the amount of wasted product, Silverson recommended reprocessing rejected material to form a percentage of the ingredients for new products, to ensure less was wasted. This required a couple of trials, to test how the crumpets would turn out: wasted crumpets were incorporated into 100 litres of water to test a usable slurry, at which point the company’s mixer disintegrated the crumpets. The mixture was passed through another mixer to produce a smooth slurry, which was then tested with rejected tortilla wraps.

The choice of the equipment is key, but both automated batch and continuous mixing technologies exist to suit the baker’s needs. Newer equipment takes into account the hygienic requirements from the get-go, by being designed to enable easy and simple cleaning and maintenance. By manufacturing equipment out of stainless steel, with fewer flat surfaces, it can have a significant impact in helping operators with their cleaning procedures.

Alternative ingredients pose more challenges

The rise in the use of alternative ingredients such as flours that span almond, coconut or chickpea for example, means bakers cannot treat doughs made up with these flours the same as traditional wheat flour. Fundamentally, the rheology of dough made from alternative flours varies in parameters such as particle size, protein content and starch composition.

These doughs have different absorption rates compared with traditional wheat flour. Some flours are thirstier than others and require more water; while others require less. This consequently affects the hydration level of the dough and the mixing process. Gluten-free doughs are more prone to overmixing or collapsing, as they lack that component that provides key structure and elasticity.

Bakers dealing with alternative ingredients need to establish how it affects the dough in the first instance and consequently, how it will affect processing. Fibre-enriched baked goods are being perceived as key to managing gut health by consumers, which sees whole grains, nuts and seeds being incorporated into recipes as good sources of dietary fibre, but they can have a big impact on processing.

In some cases, fibre is being used to reduce sugar, fat and calories to improve the overall nutritional profile of baked goods, but some product applications are better suited to being enriched with high fibre content than others that have less sugar in the first place, such as breads, biscuits and crackers. High fibre content will affect the taste, texture and appearance, alongside dough processing. A big hurdle to overcome when mixing high fibre baked bakery products is managing the water absorption and preventing the chance of the product becoming too dry, dense or crumbly.

The fibre sources can be picked carefully to minimise the impact on the mixing process. Insoluble fibres suit breads because soluble fibres can impact on fermentation and proofing. Enzymes and gluten are also ingredients leveraged to improve the overall quality of fibre enriched goods.

As the first point in production, the mixing process is sensitive to variations. It’s also crucial to forming a cohesive and evenly distributed dough. To name a few of the purposes that mixing plays besides mixing dry and wet ingredients together; it ensures hydration and water absorption; introduces air to contribute towards dough aeration and volume expansion and influences the temperature levels, which are critical to control to manage fermentation rates, enzyme activity and yeast performance. Ultimately, bakers are aiming for uniform and consistent doughs that will turn into a high-quality end baked good.

With this in mind, precise mixing technologies are sought after equipment as they hammer home this point about product quality, uniformity and consistency. While the end result is the same, how the equipment offers precision can be achieved through a number of features. Programmable controls, for example, have become a staple of newer mixing technologies for the control they give bakers over the process, taking out guesswork with the right time and temperature parameters to set for dough.

Other features such as variable speed capabilities enable bakers to adjust mixing speeds, which can be hugely important when dealing with more delicate or fragile doughs. Delicate doughs such as pastry doughs for shortcrust pastry, puff pastry or choux pastry constitute as delicate because of their high fat content and low water content that lends them their flaky characteristics. Overmixing or even failing to gently handle these doughs can result in the fine layers of butter blending in the dough, reducing the amount of flakiness and airiness.

Some mixing technologies meanwhile feature dual agitation systems in the form of dual shafts or paddles that work in tandem to ensure thorough mixing and a uniform dough consistency. They’re best applied to doughs that require thorough mixing, in particular those with high hydration levels or challenging rheological properties. Some examples include high hydration doughs like artisan breads or focaccia, doughs with stiff consistencies like pretzel or bagel, alongside doughs enriched with high amounts of ingredients such as fats, sugars or eggs.

Temperature control systems, integrated additive dispensing and auto-adjustment mechanisms are also features that reflect a greater focus on making the mixing process smoother and more seamless. The latter may include sensor technology capable of detecting changes in dough consistency, temperature, viscosity and hydration levels and report feedback to the control system; automated hydration adjustment, sees water or other liquid ingredients added to the dough based on real-time measurements of the dough’s current hydration levels; and adaptive mixing algorithms, designed to optimise mixing parameters based on real-time feedback and historical data.

These algorithms analyse dough characteristics, the performance of the equipment and the conditions in which the dough is being mixed – whether in a hot or humid environment, for instance, which can be challenging – in order to make adjustments during mixing to support consistent dough quality.

As briefly touched upon, some doughs are harder to mix than others. Pastry doughs are delicate and can be prone to crumbling. When mixing doughs with inclusions such as dried fruit pieces, nuts, chocolate chips or even seeds, bakers must take into consideration factors such as whether these inclusions are added during the mixing process or even folded in near the end to avoid overmixing as well as adjusting the mixing speed and time to ensure even distribution of inclusions without damage.

Final thoughts

Fruit doughs, gluten-free or otherwise, mixing technologies are becoming smarter and more seamless in their approach to processing a wide range of doughs as consumers look for plant-based, gluten-free and fibre-enriched baked goods, to name a few, all of which ultimately impacts on the mixing process. Smart features like sensors and temperature control systems can yield a number of significant advantages that can go a long way towards maintaining product quality and consistency.

Read more news and exclusive features in our latest issue here.

Never miss a story… Follow us on:

Showhome

@Your_Show_Home

@Showhomemag

Media Contact

Joseph Clarke

Editor, Showhome

Tel: +44 (0) 1622 823 920

Email: editor@yourshow-home.com