Bosch Packaging Technology will showcase its latest packaging system solutions for bars, biscuits and bakery at two global packaging trade shows in September. At FachPack in Nuremberg, Germany, customers will experience a scalable mid-range system, which is ideal for fast-growing companies to expand their capacities. At PackExpo in Las Vegas, USA, Bosch will showcase a high-speed integrated system solution with features that take efficiency to the next level.

“We have decades of experience in engineering packaging systems. We carefully analyse the requirements of our customers to ensure that they get a system tailored to their needs,” Martin Tanner, director product management at Bosch Packaging Technology, says. “No matter if manufacturers need an entry level system, a flexible high-speed solution or anything in between, we are able to provide the ideal solution.”

New all-round system

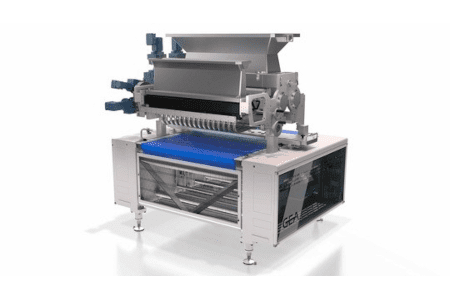

At FachPack, Bosch will launch its new all-round packaging system, which is suited for bars, biscuits and bakery products – but can also be adapted for other products. It features the new Pack Feeder 4 and the new Pack 403 horizontal flow wrapper with an output of up to 800 products per minute. The chain feeding system stands out for its easy cleanability with tool-less belt removal and gentle product handling.

The Pack 403 achieves consistent flow wrapping results thanks to its upgraded cross and fin-seal units. With decals and scales, the machine is operator friendly and features a removable discharge belt that reliably rejects faulty packages. “Our new system is a modular and scalable solution that is able to grow with the customer’s needs,” Tanner explains. “Manufacturers can easily upgrade and complement the system with extra options such as a cartoning machine.”

Efficient integrated system

At Pack Expo in Las Vegas, Bosch will showcase one version of its highly efficient seamless bar packaging systems. The exhibit consists of a high performance, indirect distribution station, a cardboard inlay feeding unit, a high-speed Sigpack HRM flow wrapping machine and a flexible Sigpack TTM1 top load cartoner.

“This system is one example of our seamless systems portfolio that provide manufacturers with highest levels of efficiency, productivity and flexibility,” Tanner explains. The displayed system features an optional cardboard inlay module. The Sigpack KA forms flat, U-shaped or O-shaped cardboard inlays, that are fed into the high-speed flow wrapper. The Sigpack HRM is equipped with an HPS high-performance splicer and is able to wrap up to 1,500 products per minute. One of the highlights of the system is the Sigpack TTM1 top load cartoner. It stands out for its high product and format flexibility.

In this configuration, the machine either loads the flow wrapped products into 24-ct display cartons or fills them directly into a WIP (Work in Process) tray. In addition, the integrated bar system is equipped with the mobile device-friendly Operations and Maintenance Assistants that are both part of the Industry 4.0-based Digital Shopfloor Solutions portfolio. These user-friendly, intuitive assistants boost operators’ capabilities and guide them through maintenance and operative tasks in a quick and easy manner.

Competence and expert consulting

Bosch Packaging Technology also offers dedicated project consulting – beginning with early planning, the choice of technology, system layout up to service packages and beyond. One major competence area is sealing technology, which is key in the packaging process. “Which sealing technology achieves the best results always depends on the product and film characteristics,” Tanner adds.

“Based on many years of experience, we offer in-depth support at our sealing testing labs, where we conduct tests together with customers to identify the best option.” Heat-sealing technology will be shown as part of the packaging system at FachPack, while cold-sealing will be shown at Pack Expo. Both systems are available with a wide range of modern sealing technologies.

Global customer services network

In addition, Bosch Packaging Technology provides access to their comprehensive global network of customer services. This includes preventive maintenance at scheduled intervals to reduce unexpected downtime and consulting services for spare part management or software updates. The Bosch training academy provides hands-on training sessions to boost equipment effectiveness. Industry 4.0-based assistance solutions complete the service portfolio.