Brabender will be presenting several instruments innovations at the upcoming iba trade fair as its new measuring technology will feature alongside the latest technologies for precise, automated and time-saving measuring processes.

From 22-26 October iba will be opening its doors to companies from all over the world. Brabender will be attending as an exhibitor. “We are looking forward to the opportunity to make contacts and exchange ideas. The iba is also the first trade fair at which we will appear together with our new parent company, the Anton Paar Group,” said Dr. Matthias Mayser, Head of the Food and Feed Application Laboratory at Brabender.

Just in time for its 100th anniversary this year, the company is presenting four new products at the trade show. The focus of the exhibition is on the new generations of the FarinoGraph, ExtensoGraph and the GlutoPeak as well as the Cubilyzer 300 – an optical measuring device for determining volume and dimensional profile of baked goods.

Attendees to the trade fair will also find solutions such as the Amylograph-E, the MT-CA moisture analyzer or the Brabender ViscoQuick. For the first time at iba, the Litsizer DIA 500, a meterological solutions from the Anton Paar Group, will be presented.

Founder of Brabender, Carl Willhelm Brabender, launched the first Farinograph in 1928. 95 years later and the company is presenting the latest version of the device, used for determining the water absorption capacity of flour and the rheological properties of doughs for quality control in line with international and national standards. The new FarinoGraph is suitable for all dough types – gluten-free, sponge dough, rye flour or hard cookie dough.

In addition to a modern device design, the FarinoGraph has a focus on automated and time-saving processes. Artificial intelligence predicts the measurement curve based on previous measurements. “The function is called Brabender Prediction, which checks and calculates the evaluation points during the measurement and makes a prediction of the torque curve in real time. With the help of this live feedback, the measurement can be ended prematurely and the predicted values used instead,” explained Viktor Schäfer, Business Development Manager Software Solutions at Brabender.

The auto-stop function ensures the device stops after the measurement is complete, which saves time. “Many customers plan a buffer time for the measurements so that the measurements are also complete. With the Auto-Stop function, this time is now eliminated as soon as all evaluation points have been reached,” added Schäfer.

The FarinoGraph forms the first stage of the 3-Phase System, which maps production of bakery and pasta products on a laboratory scale in a practical way. In the second stage, the ExtensoGraph determines processing properties and the gas retention capacity of the dough. The recorded extensogram can be used to determine reliable information on baking behaviour for example the influence of flour additives is determined.

The third stage follows with the Amylograph, which analyses the gelatinisation properties of starch, enzyme activity and baking properties of flour.

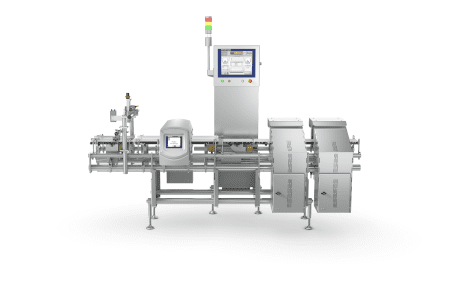

The new Cubilyzer 300 precisely and reproducibly determines the volume of bakery products such as bread, rolls, cakes, muffins and other foods in the solid state. The measurement is performed via optical inspection: “Via two line lasers and two cameras in combination with a stepper motor control, a digital 2- and 3D model is generated from which the measurement results are derived,” explains Schäfer.

As a result, the device determines parameters such as volume and volume yield, density, bread length, width, height, cross-section, weight, color and compares breads. Compared to the conventional rape displacement method according to Neumann/Doose, the Brabender Cubilyzer 300 offers a time-saving and significantly simplified measuring process without auxiliary equipment and with fast changeover and cleaning times.

Brabender is looking forward to numerous visitors after a five year back since the last trade fair. In addition to equipment demonstrations, experts at the booth will be available to answer questions regarding the challenges in quality control of bakery raw materials as well as the development of new bakery products and recipes.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

![]() International Bakery

International Bakery

![]() @int_bakery

@int_bakery

![]() @Bakeryint

@Bakeryint

Media contact

Caitlin Gittins

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com