Booth 7031

Established in Italy in 1985, CEPI is a leading Italian producer of storing, conveying and metering systems for the food industry, as well as fully integrated automation and technologies to complete all processes. This September, the company are excited to launch their new logo and website and share the essence of CEPI’s history to convey; an evolution through continuity, weaving experience and invention together to drive at the heart of technology, where power and flexibility meet.

CEPI is a family-run company with an international outlook that has centred research and adaptability since inception. Born from the encounter between an engineer’s vision and a manufacturer, it has grown into an idea factory that puts technology squarely at the centre of their work, striving to develop specialised, diversified solutions to match the most disparate needs of materials and processes.

The company’s holistic approach looks at the installation of the product rather than any of its parts, and extends to the breadth of services they provide, assisting at each stage of the project from product and process analysis, hygiene and safety management, engineering and control, manufacture, logistics, installation, commissioning, service and project management overseeing all workflow.

All our equipment is compliant with international standards including ATEX legislation and manufactured in a channelled system. Silos are made completely without seams with advanced key-hole technique to reduce the risk of contamination to zero.

With decades of experience working with the most important companies in the food industry, CEPI offer full vertical integration that makes food processing as efficient as can be.

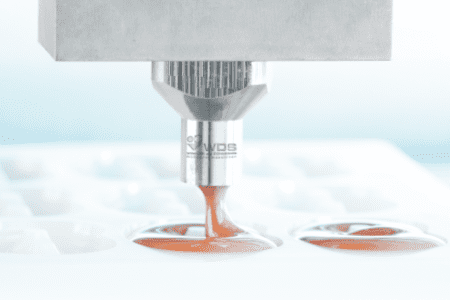

Unbroken lines smoothly carry minor, micro and macro ingredients from storage silos to metering stations, with operations managed by operator panels and software

providing full traceability and warehouse management. Along the way, the needs of any powders, granulates or liquids are met through equipment such as fermenting tanks, yeast melters, sugar mills, sugar inverters, bread re-work dissolvers, brine production, flour cooling, bread and biscuits scrap re-work systems.

CEPI built many installations optimised for whole ingredients and processes, and can equip clients with many technologies to preserve the integrity and taste of materials as well as ensuring the highest standards of hygiene and food safety. With a R&D team aggregating engineering, manufacturing and food technology expertise will be able to assist in the development of the recipe and support the client’s own innovation.

To keep bread and similar products such as pizza as natural as can be, fermentation is a must as it leads to a healthy and aromatic product while optimising resources and collapsing costs. It saves space, manpower, additives and yeast while fully preserving the characteristics of the raw materials, making the dough suppler and removing the need for improvers. Fermented bread smells and tastes better and is easier to digest, has a longer shelf life which removes the need for preservatives.

CEPI’s fermentation technology is diversified, with multiple solutions such as fermenters, yeast melters and bread re-work dissolvers for liquid sponge, rye and wheat sourdough. With a profound understanding of the materials involved and of all aspects of the process, the company provide highly versatile systems that can stand-alone or be easily integrated in the production process. Temperature control and aeration keep ingredients vital both during preparation and while stored. Design is easy to clean and CIP washing system is completely automated.

CEPI is active worldwide with a large network of partners in the five continents, and offices in Malaysia to coordinate our activities in the Asian market. The company bring to the table a global knowledge of materials, environments, and markets as well as the continued research that goes into developing around 300 unique systems every year. With the focus on customisation that pervades all aspects of our work, CEPI dedicate each project the level of individualised care it deserves.