An increasing degree of automation with higher throughput rates in production lines requires adaptable solutions for quality control; these are the reasons given by Minebea Intec for their release of their new vision systems, for the automated end-of-line quality inspection.

New systems VisioCompact, SmartInspector and VisioPointer from the company use automatic optical inspections to monitor the product at “critical points”. Using inspection points with image processing throughout the production process can detect quality-related problems quickly and efficiently – if the bakery product is irregularly shaped or damaged, for instance. Using vision systems at the end-of-line means checking for issues with packaging, for example.

Using a combination of checkweighers, metal detectors and X-ray inspection, form a complete automated vision system, where the food can pass all quality inspections withut any gaps. Depending on the requirements of their production line, the company offers three different sized vision systems: the compact SmartInspector can be integrated into existing conveyor belts, to complete inspection options without needing much space. The VisioCompact offers numerous inspection options with a minimal footprint, and the VisioPointer system offers the widest range of inspection criteria, supported by three cameras and satellite cameras for multi-sided analysis.

Adding to these solutions the Inline-Inspector, for integration into packaging machines. Cameras and lighting in these systems can be extended beyond the near-infared spectrum to hyperspectral analysis.

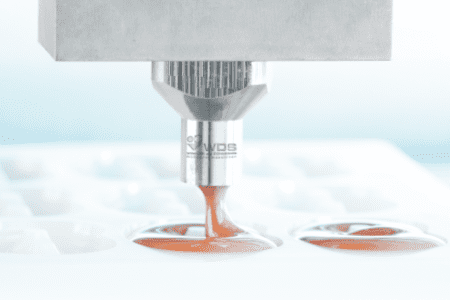

Seal seam inspection is an important part of optical quality checks, to ensure the food doesn’t go off before its best before date.

“Seal seam inspection with cameras is fast, non-destructive and adaptable. Conventional methods do not offer these advantages. We are proud to now be able to integrate this solution into our customers’ production,” explained Dr Thorsten Vollborn, Head of Product Management for Inspection Products at Minebea Intec.

Classical optical inspections such as the correct placement of a label, the reading and evaluation of the date and the readability of a barcode or QR code can all be integrated into the optical inspection and extended by further criteria related to colour, shape or placement of the product.

Using a control panel in tandem with the vision systems allows for easy operability and an intuitive user interface. VisioPointer and VisioCompact can be integrated into existing production lines and come with infeed and outfeed conveyors. An automatic rejector for defective products is also available for these systems.

Additional optical inspection contributes to reducing the risk of quality defects and the need to recall products.

“With our new portfolio of vision systems, we are expanding our footprint in the inspection systems business. This means that we can offer everything from a single source when it comes to quality control of packaged food, which is very well received by our customers,” said Willy-Sebastian Metzger, Head of Marketing and Business Development at Minebea Intec.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

![]() International Bakery

International Bakery

![]() @int_bakery

@int_bakery

![]() @Bakeryint

@Bakeryint

Media contact

Caitlin Gittins

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com