Cama Bakery cracker line: IF315 top-loading monobloc packaging machine, which delivers box forming, product loading and box closing. A very compact machine which uses an in-house developed delta-type robot which can deliver fast and efficient product loading based on any number of different recipes. The machine had to cater for four different product formats and six different box formats. Extra flexibility was a key consideration too, as the robot in the IF315 is capable of loading products onto the infeed conveyor of a downstream flowpacker, which creates flexible multipacks. The second line saw the installation of two IF296 top-loading monobloc packaging machines, both of which accept two in-feeds and package sandwich-style biscuits. In this application there is even greater variety, with seven flow-packed product formats and 11 box formats. Cama IF series offers users a unique combination of integrated packaging machines and robotic loading units. Cama has developed a machine that delivers the incredible flexibility demanded by the confectionary industry but within a reduced footprint.

Our monobloc machine is a good example of integrated packaging machines; robotic Technology; servo technology and automation solution. The main benefits of our solution are:

Easy to use machine: unique combination of integrated packaging machines and robotic loading units

Incredible flexibility for format and packaging-count changes within a reduced footprint

Modular and scalable frameworks that offer easy entry and access, coupled to a hygienic machine design

Packaging Line: top loading and side loading cartoning machines for flow wrapped biscuits into cartons

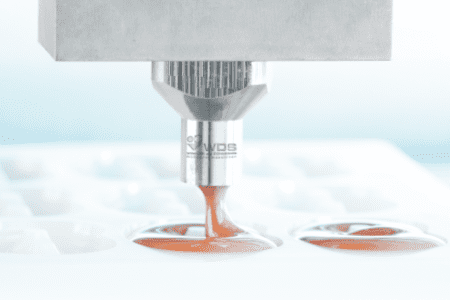

Loading unit with 2 Triaflex Delta robots feeding an high speed continuous motion side-load cartoner

Main features: packaging line for flow wrapped biscuits, coming from two lines at 360 ppm. The system consists of a loading unit with two Cama Triaflex robots feeding a CL169 continuous motion side-load cartoner.

This Cama system receives the flowpacks which are metered into a multiple pocket racetrack, from which the Triaflex robots pick a group of products depending on the format to be packed. The collation is then placed into the continuously moving bucket chain in the relevant orientation. The products can be rotated or stacked in different loading patterns, giving the possibility to produce multiple different formats with minimal change parts. The products are transferred into pre-glued cartons using an over-head pusher system. Production speed varies from 60 to 110 ppm.

Our packaging line is a good example of robotic solutions ; automation solutions; accessibility and modularity; energy saving engineering and cabinet free technology. The main benefits of our solution are, high flexibility and ability to handle a variety of products and packaging configurations

production efficiency, through guaranteed machinery uptime ease of use – through quick and easy size changing procedures

For further information on our bakery solution visit: https://www.camagroup.com/portfolio-items/biscuits-bakery/

Read the full article in our Novmeber-December issue here: International Bakery (pagesuite.com)

Media contact

Roshini Bains

Editor, International Bakery

Tel: +44 (0) 1622 823 92.2

Email: editor@in-bakery.com