Enabling producers to create a wide variety of baked goods of high quality is a major priority for FRITSCH and with the new IMPRESSA bread line, they do exactly that

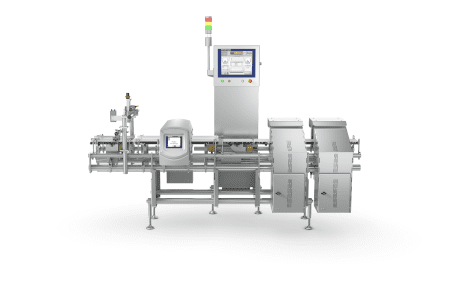

The new IMPRESSA bread line, making its debut at iba 2023, is much more compact than its predecessor. Thanks to the open design, it also runs more hygienically and is easier to clean. The modular design of the IMPRESSA bread allows producers to change the line over to new products quickly and without tools. Thus, they can produce a wide variety of rustic baked goods of the highest quality – and that is the measure of all things for FRITSCH.

With its open design and removable modules, the IMPRESSA bread is readily accessible, making it quick and easy to clean. Important components such as the conveyor belt table of the Soft Dough Sheeter (SDS) and the Soft Dough Roller (SDR) can be removed from the line in a few simple steps and taken to the washing area for thorough cleaning.

The hygienic design of individual components includes consistent use of smooth surfaces, watertight covers on threaded connections, and rounded corners where no dirt can accumulate. Fold-up knife edges, like those on the feed table of the calibrating head for example, ensure good accessibility even in relatively tight spaces. The drives on the line are also new. On the so-called “omega drives”, the belt can be completely relaxed in a matter of seconds, which makes cleaning under belts a quick and easy process as well.

Another factor in its hygienic design is the extremely sparing use of separating agents for producing the dough sheet. The use of oil is a known problem since it not only increases the effort of cleaning but also creates longer downtimes when changing products. More importantly, oil worsens the baking results and therefore degrades the final product quality. All the improvements made allow the various modules of the line to be washed down quicker and with less cleaning products than before, so that each time the IMPRESSA bread will be up and ready again for production much faster.

The line appearing at iba is now about 20% shorter than before, for the same output as before. This is accomplished in part by a new sheeting technology, which has already proven itself in the PROGRESSA bread and has now been adapted to the industrial processing lines. An important part of this is the FRITSCH Soft Dough Sheeter (SDS). It uses fold-up conveyor belts to flour the dough sheet from all sides, thereby eliminating the need to use any oil when rolling out the dough. A sensor monitors how much dough is in the hopper. If it falls below a certain level, new dough is brought with a conveyor belt. This allows for greater precision and more even weight distribution when producing the dough sheet.

Next, the dough is rolled out gently by the Soft Dough Roller. The new technology produces a highly uniform dough sheet with extremely well-defined edges and without shearing forces or the use of separating agents. This reduces scrap dough to a minimum throughout the rest of the process...

Read the full feature in our free to download magazine.

Never miss a story… Follow us on:

![]() International Bakery

International Bakery

![]() @int_bakery

@int_bakery

![]() @Bakeryint

@Bakeryint

Media contact

Caitlin Gittins

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com