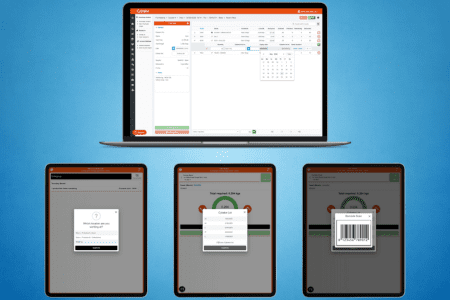

Metal detection and X-ray are often viewed as competing technologies. Yet, used together they add an additional – and often necessary – layer of recall security, food safety and quality control. Phil Brown, Sales Director at Fortress Technology Europe, explores the benefits of both inspection systems at the upcoming PPMA 2024 trade show (Stand B32), where Fortress will also unveil its latest innovation, the Icon X-ray.

Discover the most prevalent contaminant risks in the food industry and gain insights into when and how to deploy each technology, as Phil Brown answers the most common questions customers pose about metal detection and X-ray.

Q: What new demands are you witnessing from the industry in relation to food safety solutions and how can I future proof my inspection investments?

A: Overall there is a wider adoption of all inspection technologies. Countless customers have reported retailers specifying both metal detection and X-ray systems to strengthen and fulfil their food safety promise to consumers. The threat posed by a recall and enhanced quality control standards are certainly driving food factories to implement a more robust, ‘best in class’ contaminant detection strategy.

Yet, there remain a number of misconceptions in the industry about which inspection system to implement. Many food processors and packing facilities believe that having one inspection technology, like metal detection or X-ray, is sufficient for complete quality control. In reality, it is not that straightforward. Neither supersede the other and both technologies offer certain strengths, as well as contaminant detection limitations.

Q: Do food processors have to have inspection systems? What role does this equipment play in food safety management?

A: There are certain legal standards with regards to food safety that must be met in relation to hygiene and pest control. But it is the retailer or hospitality venue that is legally responsible for making sure that the food they sell is safe for consumers to eat. That’s why they set stringent codes of practice for suppliers to adhere to, including inspection standards.

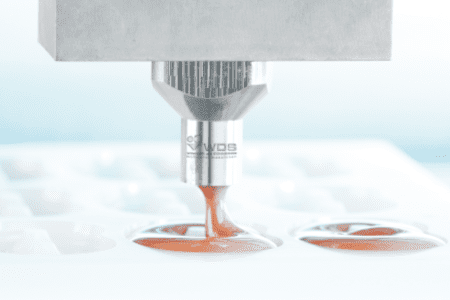

Hazard Analysis and Critical Control Point (HACCP) plans underpin most food safety management systems. Metal detection and X-ray inspection technologies are first lines of defence in identifying the presence of foreign contaminants in food products before they leave the facility. They are typically implemented at Critical Control Points to eliminate physical contaminants, ensuring high quality and safety of food products before they reach consumers.

Since metal remains the most common contaminant material in food, most retailers stipulate that metal detection systems are used to provide compliance with food safety standards (GFSI, BRC, IFS), their own codes of practice and legislations.

Q: What are the most common physical contaminant hazards food processors should look out for and how do I determine the inspection technology or combination of technologies best suited to my food applications?

A: The most common high-risk contamination culprit remains metal. Metal is found everywhere in food production, especially stainless steel. Contaminants are often caused by fragments that break off during mechanical cutting and blending operations, or from box blade cutters.

Each food sector will typically have its own set of more prevalent risks. Take ready-meals or convenience foods; some of those processes require eight or more production steps. Plus, more than five different product types can be included in one individual meal. The more production steps, the greater the risk of foreign object contamination.

Intrinsic contaminants are common in protein ingredients, such as bones or teeth from fish, meat and poultry. They can also occur in fresh produce, for example, fruit and vegetable pits or eggshells. The other is human PPE risks from hairnets and masks.

The decision to invest in X-ray or metal detection equipment is dependent upon a manufacturer’s requirements. Both technologies come with their own advantages, though neither should be a replacement for good manufacturing practices. Rather, food contaminant detection units should always complement the process based on needs and risks. To assist with decision making, Fortress Technology offer food processors a service that tests products on both a metal detector and an x-ray system. Customers are then presented with detailed reports and analysis to help inform their CapEx decisions.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

International Bakery

@int_bakery

@Bakeryint

Media contact

Joseph Clarke

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com