Newsmith Stainless Limited and Blueprint Automation (BPA) give further insight into how developing stacking and feeding systems can minimise costs and integrate a seamless system.

Does your process include the stacking and loading products such as fresh and frozen baked goods (pancakes, waffles, etc.), formed patties and fragile products such as tortillas?

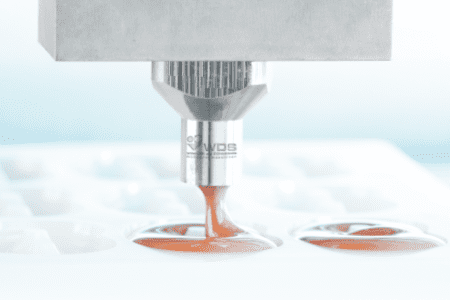

Blueprint Automation (BPA) says stacking and loading solutions unburdens the process with a patented end-effector that allows for single picks of individual products. This solution is proven to have significantly less breakage, jams and downtime than mechanical stackers, which increases your efficiency, output and continuity. Once a stack is formed, the BPA robot loads the entire stack into various horizontal form, fill and seal machines, including continuously moving flow wrapper chain infeeds or indexing thermoform machines.

Accepting the product from the bulk is done with their proprietary feeding technology. This stacking and loading solution increases traditional robot productivity by up to 50%, ensuring a quick ROI on the customer’s investment.

Automated handling solutions

Newsmith is one of the leading manufacturers of washing, drying and handling equipment for a wide range of industries, including bakery. Formed in 1969, Newsmith Stainless Limited has remained a family-owned business and its main production facility is in Liversedge in West Yorkshire situated in an ideal location between Leeds and Manchester. The establishment of fully-owned subsidiary Newsmith sales offices in Germany and the U.S.A. and has been followed by development into markets throughout Asia, the Middle East and Eastern Europe.

Newsmith Stainless specialises in a variety of automated handling solutions designed to minimise labour costs and operator error in a range of industries. From distribution baskets to bread tins and raw food products, Newsmith’s dedicated handling division can offer turn-key systems or integrate seamlessly with a customer’s existing production equipment.

The Newsmith basket stacker can be supplied as a stand-alone unit or integrated within an automated basket handling system. The system automates the stacking of baskets or crates, reducing manpower at the end of production lines.

The Newsmith basket stacker can be supplied as a stand-alone unit or integrated within an automated basket handling system. The system automates the stacking of baskets or crates, reducing manpower at the end of production lines. As standard, the stacker is manufactured from stainless steel and is designed around the customer’s specification on basket size and throughput rates.

The unit is supplied with hygiene, maintenance and safety in mind incorporating integral pneumatic and electric panels as part of the main frame. Controlled from an HMI, variables such as stack height, infeed conveyor speed and stack transfer speed can all be adjusted with ease.

Options which can also be included are: –

- Servo controlled movement for high speed applications

- Bale arm turners

- Pre-stack turntable

- Rear guides for tall stack heights

- Integrated dolly loader

The Newsmith Basket Loader is designed for the high speed loading of bread and roll products into distribution crates or baskets. The Newsmith basket loader can handle over 100 pieces per minute and organise product orientation in the most complex of patterns.

Often integrated into Newsmith product and crate conveying systems to provide a complete handling and packaging solution, the Newsmith basket loader is designed for gentle, efficient handling and built to ensure robust reliability.

- Basket Loading Rate 85 loaves/min

- Basket can be loaded both ways with no change parts

- Basket rotation on infeed and discharge for correct orientation

- Pattern is selected through HMI

- Pattern editing on screen

- Servo control on Pusher and Retracting Conveyor

- Integrated with upstream and downstream equipment

- Light curtain safety system

CASE STUDY

The installation of an Oliver Douglas Trayline 2 to Hertfordshire’s family bakers Simmons has enhanced their production facility.

The Customer: Simmons Bakers

Country: UK

Industry: Bakery

Founded: 1838

Employees: 400

Website: www.simmonsbakers.com

Simmons runs a 24/7 operation to keep their shops supplied. They currently have 35 shops, all within a 25 mile radius of their bakery to ensure the freshness of the bread & rolls, cakes & pastries, cream cakes, pies & tarts and tray bakes.

The machine is designed to be operated by one person. Trays are loaded by placing them base down one at a time for movement along the roof of the machine, at the end of which they are inverted as they turn and are taken up by the conveyor. This automatically feeds them in a controlled manner through the wash chamber with washed and rinsed crates then delivered back to the same operator.

In line with the site limitations, the machine requires only a small footprint. Capable of handling up to 200 crates per hour, it has been configured to accommodate the specific Simmons crate dimensions and design.

Paul Careless, Sales Manager at Newsmith Stainless, worked closely with Rupert Matthews, Managing Director of Simmons Bakers, to ensure that the machine, wiring and extraction were all bespoke to suit the facility and maintenance requirements.

Rupert Matthews comments: “Simmons are very impressed with the new Trayline washer which was recently installed. The machine comfortably met the initial brief to provide cleaner and dryer trays. We were also pleased with the installation process which had the machine running the same day as delivery.”

“It was really satisfying to hear the customer say, “Wow that’s fantastic!” as they saw the level of dryness and cleanliness as the first few trays came out of our machine during our commissioning. They hadn’t been used to that with their previous unit” Paul Careless concludes.