Ashworth continues to lead the market with its revolutionary conveyor belts, offering the best customised solution for your specific requirements

Ashworth Belts B.V., a global company, is the only conveyor belt company that manufactures and services both metal and plastic belting for straight running, turn-curve, lotension, direct drive, and self-stacking spirals—offering you the best customised solution for your specific requirements. Celebrating over 75 years of revolutionising the future of conveyor belts, Ashworth continues to lead the market with the most conveyor belt patents in the baking industry.

An Industry Pioneer

Hybrid Belting. Ashworth pioneered hybrid conveyor belting, introducing belts that combine a backbone of steel for high strength with a plastic product surface for its functional advantages. Ashworth introduced The Advantage®, a line of hybrid belting, that provides a hygienic, easy to clean, open conveying surface combined with a no-weld, patented rod-locking system that makes repairs a snap.

True-Tracking Friction Driven Belts. Ashworth developed the true-tracking CB5 Baking Band® that became, and still is, a standard in the baking industry, as well as Cleatrac®, a positive-drive woven-wire belting system that eliminated the need for pin rolls.

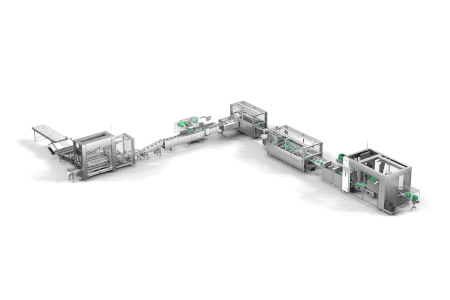

Lotension Spiral System and Spiral Belts. Ashworth invented the Lotension Spiral Conveyor System and the related turn curve conveyor belts that became a worldwide standard in food processing equipment for cooking, freezing, proofing and cooling applications.

Innovation

The PosiDrive Spiral® System. Ashworth’s PosiDrive Spiral System, the original direct drive, features a unique drive design that is designed for heavier loads, eliminating jam-ups, and helping to streamline packaging.

Ashworth’s SpiralSurf® Plastic Belt Line. Like their metal counterparts, Ashworth’s SpiralSurf belts can be customised to meet individual requirements for cooling, proofing, and freezing applications. The durable plastic line has been tested and proven to operate over 100,000 cycles. Ashworth’s SpiralSurf 100 is perfect for tight transfers and smaller products, while the SpiralSurf 200 is ideal for heavier/larger products.

The SmartSpiral® Monitoring System. Ashworth offers the SmartSpiral Monitoring System – an innovative application that provides real-time remote monitoring using predictive analytics to minimise production downtime. The SmartSpiral allows access to multiple spiral/plant locations from your phone and tablet to continuously monitor spiral temperature, belt tension, cage power and features the industry’s first, patented bottom bearing wear sensor.

The Omni-Grid® 360 Weld Belt. Ashworth’s Omni-Grid 360 Weld belts are engineered to meet a strict hygienic design criterion. Our patented coining process ensures a corrosion-resistant, mechanically smooth, and stable belt that’s easy-to-clean, offers added strength, reduces wear, and increases belt-life. Our goal is to eliminate areas where bacteria can grow, making overall food processing safer and more efficient.

Proven Partner

Ashworth Factory Service. Ashworth Factory Service offers a full range of engineering services, including system refurbishment, troubleshooting, and belt installation. Ashworth Factory Service is available 24 hours a day, 365 days a year.

Companies around the world depend on Ashworth’s quality products, reliable customer service, and innovative solutions to resolve problems and increase productivity. As your industry partner, Ashworth offers global expertise to optimise the function and mechanics of baking conveyor systems that are key to keeping your business running smoothly.