The PROGRESSA bread line from FRITSCH allows mid-sized bakers to produce high-quality, precision products

PROGRESSA bread, the compact bread line from FRITSCH, allows mid-sized retail bakers to produce a large variety of products in high quality with extreme precision in weight. The line is also quick and easy to retool, clean and expand. Depending on product size, the PROGRESSA bread can process up to 1.8 metric tons of dough per hour – and that in a processing quality and product variety only seen before in the category of industrial lines. The space-saving solution combines a sophisticated hygiene concept with highest product quality in a very compact space.

Hygienic design

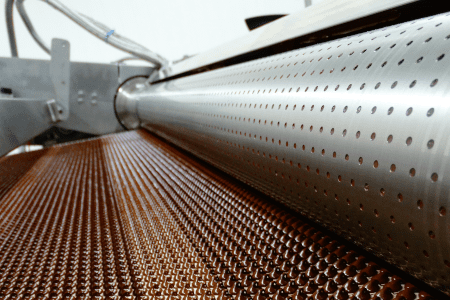

In the development of the PROGRESSA bread, great importance was given to ensuring that all parts are readily accessible and easy to remove. Important components such as the conveyor belt table of the Soft Dough Sheeter and the Soft Dough Roller can be removed from the line in a few simple steps and taken to the washing area for thorough cleaning.

Another big plus of the PROGRESSA bread is that the amount of oil needed for processing the dough sheet has been reduced to a minimum. Only in the hopper and the star rollers of the dough sheeter, the minutest spray with just enough oil keeps the dough flowing uniformly. There is no need to use any oil for rolling out the dough sheet, thanks to the special design of the dough sheeter SDS nano. A clever system of fold-up belts flours the dough sheet from all sides. This prevents oil inclusions in the dough, which in turn guarantees excellent baking results of the finished breads. On top of that, it lowers the cost of oil consumption and reduces the effort of cleaning.

Product quality and flexibility

The line can be used to process pre-proofed doughs as well as doughs with a high rye or water content in the same quality as on a large-scale line. The SDS nano and the Soft Dough Roller produce a consistent dough sheet, which is processed very gently to preserve the structure of the dough. This is the basis for high quality end products. The weighing system of the PROGRESSA bread features two weighing units. The first weighs the dough sheet immediately before cross-cutting. As soon as the desired weight is reached, the guillotine is released, and the dough sheet is cut into individual pieces for further processing. The second weighing is done immediately afterwards. If the weight of the dough pieces deviates from the target weight, the cutting process is corrected accordingly.

From here, the options for further processing the precisely cut dough pieces are wide open. Depending on what you prefer, manual processing on a worktable is just as possible as using a baguette moulder or a belt round moulder to produce round loaves. Furthermore, FRITSCH offers a lift tipper specially adapted to the line. Customers can use it for refilling up to 250 litres of dough to guarantee a continuous production process.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

International Bakery

@int_bakery

@Bakeryint

Media contact

Joseph Clarke

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com