European Process Plant (EPP) has reported developing a fruit hydration system in response to a customer’s issues with processing fruited dough. The new solution, which features a Vacuum Tumbler, hydrates dried fruit prior to being added to the dough, providing customers with cost savings and preventing the dough from drying out.

“We were delighted to create this solution to address our customer’s persistent issue with its fruited dough drying out,” explained Stewart Morris, Sales Director, EPP. “The system gives bakers precise control of dough moisture content. Now, bakers can save costs by using dried fruit – instead of more costly rehydrated dried fruit – which can then be hydrated using specific liquid dosages. This can be water or any other liquid to flavour the fruit, such as fruit juice. It’s a prime example of how EPP can provide solutions to address industry challenges, and we’re now pleased to offer it to the wider market.”

Traditional methods of fruit soaking when working with fruit dough leave some of the process to chance and depends on variables related to soaking duration, temperature fluctuations, agitation levels and the arduous task of breaking up compacted fruit prior to soaking. Busy operators with lots to do are challenged with other tasks to complete at the same time and can lead to inconsistent results.

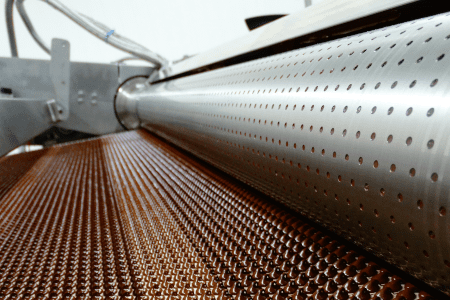

In EPP’s fruit hydrating and batch weighing system, unpacked fruit (such as raisins and sultanas) is loaded in the euro bin which tips into a vacuum tumbler. The tumbler then delicately breaks up clumps of fruit into free-flowing individual pieces. The weight of the fruit added is weighed by the system, and the required liquid percentage is dosed automatically. The dried fruit is then tumbled under vacuum to hydrate and soften. Trials tested using this system demonstrated that up to 10% moisture can be added to the fruit in this system leaving a free-flowing batch without surface moisture.

The complete system includes a euro bin elevator, vacuum tumbler, feed conveyors, loading hopper, tub loading roller bed with integrated weight scale, control functionality and perimeter guarding.

Read more latest industry news and developments in our free to download magazine.

Never miss a story… Follow us on:

![]() International Bakery

International Bakery

![]() @int_bakery

@int_bakery

![]() @Bakeryint

@Bakeryint

Media contact

Caitlin Gittins

Editor, International Bakery

Tel: +44 (0) 1622 823 920

Email: editor@in-bakery.com